top of page

HOW DOES VICELOADER OPERATE?

On the pages below, we will introduce the unique features of Viceloader:

In the principle, there are 2 types of automation (direct clamping and external clamping)

The automation system loads individual workpieces directly into the CNC centre where the workpieces are clamped in a special vice. Workpieces are gripped separately by the special automation holders. Each workpiece needs a different gripper.

DIRECT CLAMPING:

Advantages:

►ideal for large-lot contracts

Limits:

►each workpiece needs a different gripper (effector), magazine and vice.

►ideal for large lots of identical workpieces

Ideally, VICELOADER can be used for both variants,

external and direct clamping.

As a standard we offer the smart solution version = external clamping

EXTERNAL CLAMPING:

The operator attaches the workpieces to pallets or directly into vices to be placed into the magazine. The automation system picks and places a whole pallet or the vice with the workpiece into the CNC centre.

Advantages:

►clamping by operator = 100% safety

►ideal for small and medium-batch production

►highly reliable, easy and safe

►workpieces may differ in size and shape

Limits:

►each workpiece requires a pallet or vice

VICELOADER is Plug & Play

in the external clamping version.

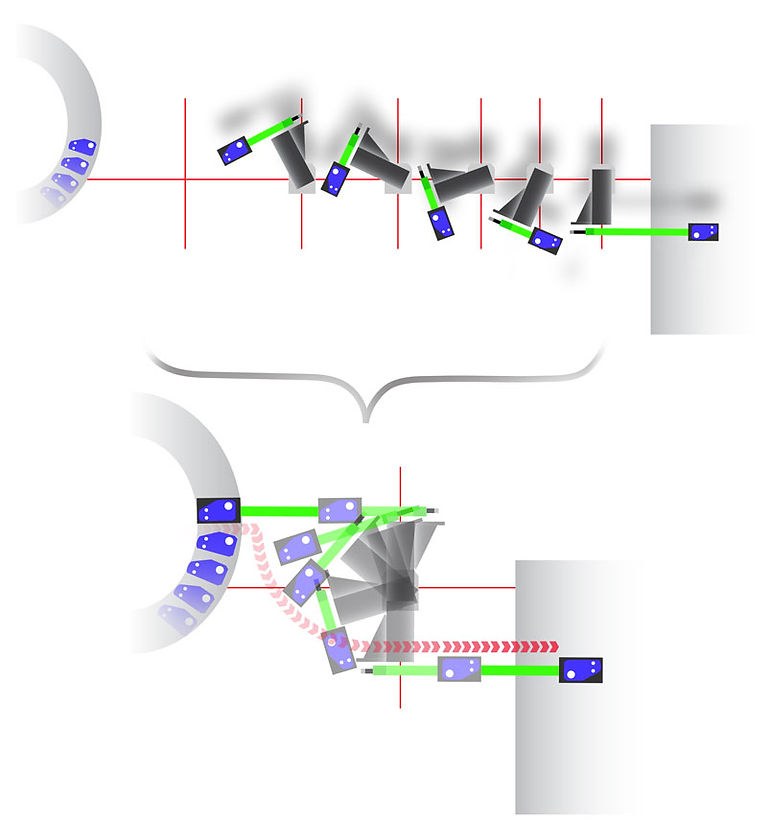

Function of the Patented Viceloader Arm

(profile)

Viceloader’s innovation consists in the capability of the horizontal movement of the arm

Bionic arm movement is based on the natural movement of a man, but it has a larger range.

Magazine

Workpieces

(individual steps of movement)

CNC

CNC

Magazine

Workpieces

(complex movement)

movement of the arm with the workpiece

this illustrates the part from the magazine into the CNC centre

(ground plan)

The actual Viceloader layout allows for

easy access to the CNC centre

Workpieces

Magazine

Manual

mode

Automatic mode

If Viceloader is in standstill mode, the CNC centre is fully accessible for manual activities.

CNC

CNC

Workpieces

Magazine

Viceloader is not much bigger

than 2 pallets

Example of the smallest automated plant equipped with the Viceloader automation system.

to save space and finances, we created a special magazine

access from all sides

and to all workpieces

topping, exchange and measuring during production

circular magazine with rotary levels

the magazine can be easily filled thanks to the door

magazine

with

workpieces

View into the rotary magazine of Viceloader in the version with pallets – 300 x 400 mm

View into Viceloader's magazine equipped with pallets

1| protective fence jacket 2| Viceloader arm 3| protective belt for cable line

4| rotary magazine 5| pallet picking interface 6| pallet 7| rotary level of magazine

8| electrical cabinet

Viceloader's magazine is a rotary type and it allows for full modification as specified by the user.

The magazine is composed of various types of levels. Individual levels are fully selectable

depending on the dimensions of workpieces and pallets.

Fully selectable levels are derived from the

sizes of vices and pallets that are put onto the levels.

Viceloader is standardly supplied with one level.

For detailed information on rotary level options, see Chapter "Magazine"

example of the arrangement of pallets and vices

onto all of the level types of Viceloader:

Viceloader has four wheels, two rotary and two fixed,

which allow for the easy and quick movement of Viceloader.

Viceloader has a set of legs for fixed placement.

Viceloader can be moved manually on a pallet truck or with a high-lift truck

4 možná uspořádání pracoviště s ustavením Viceloaderu k CNC stroji

1 loading from the front side

2 loading from the lateral side

3 loading from the lateral side

4 loading from the lateral side

Install legs to more machining centres. Viceloader movement and anchorage to the points prepared in advance will take several minutes without the need for positional levelling. As a matter of course, we also offer a spare set.

The green colour indicates the work area for Viceloader. We tried to use the area to the full extent.

An example of the smallest fully automated workshop equipped with the Viceloader automation system..

thanks to the full-featured CNC control, the Viceloader automation system can be controlled very easily and the four-axis movement is fully programmable

Viceloader can be connected to any CNC centre

In contrast to competitive solutions, the Viceloader control system does not require any special knowledge of robotics.

Interconnection between CNC centre and Viceloader

Simple connection of Viceloader and CNC centre

All the communication needs is one M-function only

Customers are capable of the connection completely on their own

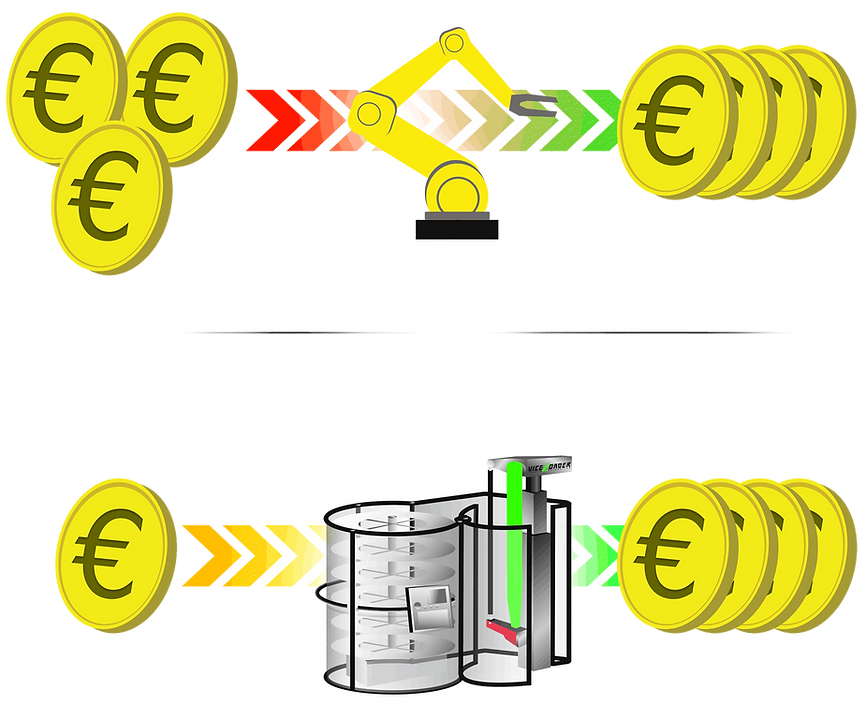

With Viceloader you will spend less money than you expect

Viceloader is cheaper than all of the common automation systems

Investments

Profit

common automation systems

vs.

Viceloader

For more informations leave us the message please.

We will answer as soon as possible.

Viceloader team.

Please sign in or register to download the current catalog.

bottom of page